Mineral fiber board insulation is a reliable material crafted from inorganic mineral fibers. It excels in thermal insulation, sound absorption, and fire resistance. You can count on its durability and non-combustible nature to enhance safety and comfort in buildings.

Mineral fiber board insulation is a reliable material crafted from inorganic mineral fibers. It excels in thermal insulation, sound absorption, and fire resistance. You can count on its durability and non-combustible nature to enhance safety and comfort in buildings.

Its effectiveness stems from research-backed data:

Thermal conductivity values hover around 0.040 W/(m K), similar to fiberglass.

Density explains 68.5% of the variability in resistance, while thickness accounts for 85%.

Durability tests show no penetration or damage under impact, outperforming other systems.

This insulation plays a vital role in energy-efficient and sustainable construction practices.

Key Takeaways

Mineral fiber board insulation keeps indoor temperatures steady. It also lowers energy bills.

This insulation does not burn, making buildings safer in fires. It gives people more time to leave during emergencies.

Its thick design blocks noise, creating quieter spaces at home or work.

Using mineral fiber board insulation is eco-friendly. It has up to 70% recycled materials and reduces pollution.

Installing it correctly is very important. For tough jobs, hire experts.

What is Mineral Fiber Board Insulation?

Image Source: pexels

Composition and Structure

Mineral fiber board insulation is crafted from inorganic mineral fibers, primarily basalt or dolomite rocks. These materials undergo a high-temperature melting process, typically around 1500°C, to create durable fibers. The fibers are then bonded together using a resin binder to form rigid boards. This composition ensures the material’s non-combustible nature and exceptional durability, making it suitable for demanding environments.

The ASTM C612 standard outlines the classification and physical properties of mineral fiber board insulation. It specifies that this insulation is designed for high-temperature applications, emphasizing its ability to withstand extreme conditions without compromising performance. The standard also highlights its fire resistance, tensile strength, and compressive strength, which are critical for modern construction.

Empirical studies further detail the manufacturing process and composition:

Aspect

Details

Thermal Conductivity

Measured at Agosti Nanotherm Company.

Sound Absorption Coefficient

Evaluated at the Acoustics Labs of the University of Perugia.

Materials Compared

Basalt fiber panels vs. Rock Wool, Glass Wool, Expanded and Extruded Polystyrene.

Key Characteristics

Thermal performance, acoustic insulation, fire resistance, tensile and compressive strength, etc.

Manufacturing Process

Basalt fibers are produced similarly to glass fibers, with lower energy consumption and no additives.

Composition

Basalt is primarily composed of Al2O3 and originates from frozen lava.

Melting Temperature

Basalt fibers are produced at approximately 1450 °C.

Application

Potential use in building refurbishment and analysis of thermal transmittance for existing walls.

This robust structure ensures mineral fiber board insulation performs reliably across various applications, from residential buildings to industrial facilities.

How It Works as an Insulation Material

Mineral fiber board insulation operates by minimizing heat transfer through its dense fiber composition. The fibers trap air within their structure, creating a barrier that reduces thermal conductivity. This mechanism ensures consistent indoor temperatures, lowering energy consumption and enhancing comfort.

Scientific data supports its effectiveness:

Type of Mineral Fiber

Manufacturing Process

Thermal Conductivity (W/mK)

Density (kg/m3)

Glass Wool

Made from borosilicate glass melted at 1400°C and fiberized using centrifugal force.

0.054–0.068 at 100°C

240–400

Rock Wool

Made from basalt or dolomite rocks melted at 1500°C and fiberized using rotating discs.

0.054–0.068 at 100°C

240–400

The dense structure also contributes to sound absorption. It dampens vibrations and reduces noise transmission, creating quieter indoor spaces. Additionally, its non-combustible nature provides a critical layer of fire protection. The material resists ignition and slows the spread of flames, enhancing building safety.

By choosing mineral fiber board insulation, you gain a versatile solution that addresses thermal efficiency, noise reduction, and fire safety. Its unique properties make it an essential component in sustainable construction practices.

Benefits of Mineral Fiber Board Insulation

Thermal Efficiency and Energy Savings

You can rely on mineral fiber board insulation to improve your building’s energy efficiency. Its dense fiber composition traps air, creating a thermal barrier that minimizes heat transfer. This feature keeps indoor temperatures stable, reducing the need for excessive heating or cooling. As a result, you save energy and lower utility bills.

The material’s low thermal conductivity ensures consistent performance even in extreme weather conditions. For example, its ability to resist heat flow makes it ideal for both hot and cold climates. By choosing this insulation, you contribute to a more sustainable future by reducing your carbon footprint.

Fire Resistance and Safety

Safety is a top priority in any building, and mineral fiber board insulation excels in fire resistance. Its non-combustible nature prevents ignition and slows the spread of flames. This property provides critical protection, giving occupants more time to evacuate during emergencies.

Unlike some other insulation materials, mineral fiber boards maintain their structural integrity under high temperatures. This durability ensures that the insulation continues to perform effectively, even in challenging conditions. When you use this material, you enhance the overall fire safety of your building, making it a safer place to live or work.

Acoustic Properties for Noise Reduction

Mineral fiber board insulation doesn’t just regulate temperature; it also improves sound quality. Its dense structure absorbs sound waves, reducing noise transmission between rooms or from external sources. This makes it an excellent choice for creating quieter indoor spaces, whether in homes, offices, or industrial facilities.

Acoustic performance measurements highlight its effectiveness:

Measure Type

Description

Sound Absorption Coefficient

Indicates how much sound a material can absorb, with higher values indicating better absorption.

Noise Reduction Coefficient (NRC)

A single-number rating for sound absorption, tested per ASTM C423; higher values indicate better performance.

Sound Transmission Class (STC)

A rating for sound attenuation of partitions, tested per ASTM E90; higher values indicate greater sound reduction.

When you choose mineral fiber board insulation, you gain a material that balances thermal efficiency, fire safety, and noise reduction. Its versatility makes it a valuable addition to any construction project.

Environmental Impact and Sustainability

When you choose mineral fiber board insulation, you’re not just improving your building’s performance—you’re also making an eco-friendly choice. This material offers significant environmental benefits throughout its lifecycle, from production to disposal. Its sustainable properties make it a standout option for reducing your carbon footprint.

One of the key advantages lies in its composition. Manufacturers use up to 70% recycled content to produce mineral fiber boards. This reduces the demand for raw materials and minimizes waste. By opting for this insulation, you support a circular economy that prioritizes resource efficiency.

The energy savings achieved with mineral fiber board insulation further enhance its sustainability. Studies show that residential buildings using this insulation can reduce energy consumption by up to 30%. This translates to lower utility bills and less strain on energy resources. Over time, these savings contribute to a significant reduction in greenhouse gas emissions.

Environmental assessments highlight the material’s low impact during manufacturing. The production process consumes less energy compared to other insulation types, thanks to the use of recycled materials and efficient techniques. Here’s a breakdown of its eco-friendly benefits:

Category

Data

Recycled Content

70%

Energy Savings (Residential)

30% reduction in energy use

CO2 Emissions Avoided

1.5 million tons annually

The sustainability of mineral fiber board insulation extends beyond energy savings. It also performs well in waste management. The material is durable and long-lasting, which reduces the need for frequent replacements. At the end of its life, it can be recycled, further minimizing its environmental impact.

Here’s how its lifecycle contributes to sustainability:

Energy used during manufacturing is carefully managed to reduce emissions.

The insulation’s application in buildings leads to significant energy savings.

Recycling at the end of its lifecycle prevents waste from ending up in landfills.

By choosing mineral fiber board insulation, you’re investing in a solution that benefits both your building and the planet. Its eco-friendly properties align with modern sustainability goals, making it a responsible choice for environmentally conscious construction.

Applications of Mineral Fiber Board Insulation

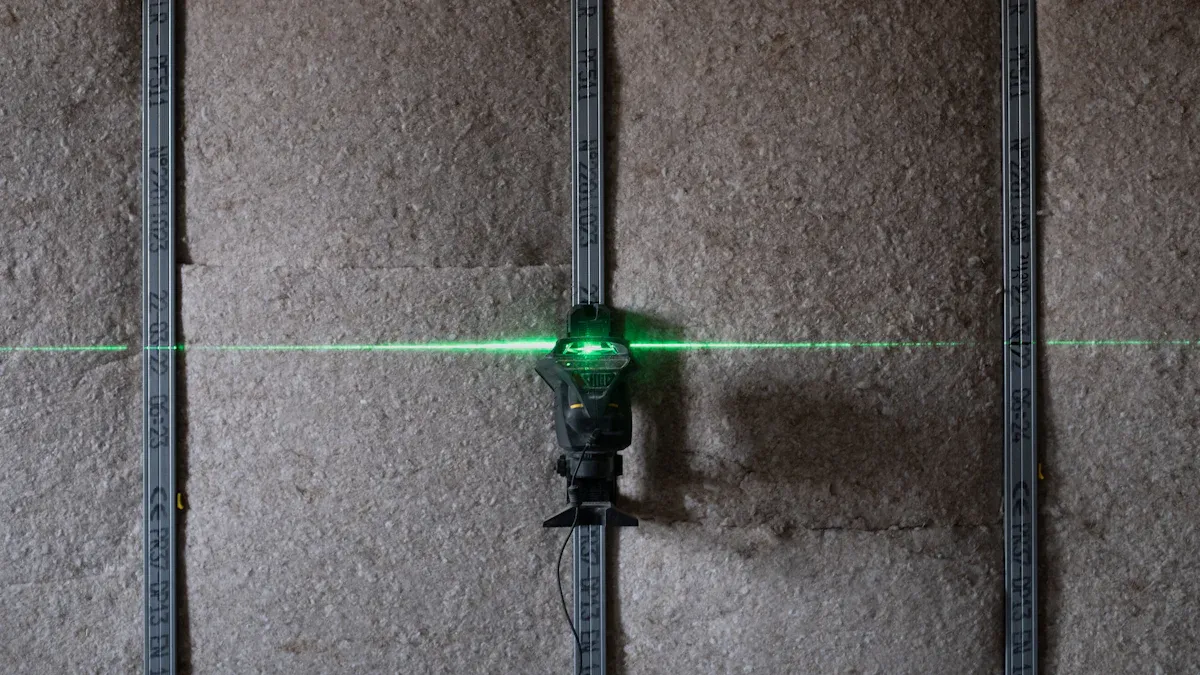

Image Source: unsplash

Roofing Systems

Mineral fiber board insulation enhances the performance of roofing systems by providing superior thermal and moisture control. Its ability to resist heat transfer ensures stable indoor temperatures, even during extreme weather conditions. This makes it an excellent choice for energy-efficient homes and buildings.

Field studies highlight its effectiveness in roofing assemblies. For example, a large-scale monitoring project in British Columbia examined how insulation strategies impacted heat flux and surface temperatures. The findings revealed that mineral fiber board insulation significantly improved thermal performance, especially when paired with reflective roof membranes.

You can also rely on this material for moisture durability. A guideline for high-performance enclosure retrofits emphasizes the importance of exterior insulation, including mineral fiber boards, for wood frame roofs and concrete foundations. This approach not only boosts energy efficiency but also protects against moisture-related damage, ensuring long-term durability.

Walls and Ceilings

Mineral fiber board insulation offers exceptional benefits for walls and ceilings. Its dense composition minimizes heat transfer, helping you maintain comfortable indoor temperatures year-round. This insulation also provides fire resistance, adding an extra layer of safety to your building.

Comparative studies show its competitive performance against traditional insulation materials. For instance, simulations using Energy Plus software assessed the thermal efficiency of walls with mineral fiber board insulation. The results demonstrated improved time lag and decrement factor, which are critical for energy savings.

Building codes also recommend specific configurations for walls. For optimal performance, use steel studs spaced at a maximum of 24 inches on center, combined with mineral wool insulation friction fit in each stud cavity. This setup ensures effective thermal and acoustic insulation while meeting industry standards.

Wall Component

Materials Used

Studs

Minimum 20-gauge steel studs spaced at a maximum of 24 in. OC

Insulation

Minimal 4 lb/ft³ mineral wool insulation friction fit in each stud cavity

HVAC Systems and Ductwork

Mineral fiber board insulation plays a vital role in HVAC systems and ductwork. It improves energy efficiency by reducing heat loss and gain, ensuring consistent airflow temperatures. This insulation also enhances fire safety and sound control, making it a versatile solution for modern buildings.

Case studies, such as the Minerva Primary Academy project, demonstrate its effectiveness. ROCKWOOL’s DuoDuct and Ductwrap products were used to insulate HVAC systems, achieving compliance with building regulations for thermal and noise reduction. These materials helped create a safer and more comfortable indoor environment.

You can count on mineral fiber board insulation for its environmentally friendly qualities. Its thermal performance reduces energy consumption, while its sound control capabilities minimize noise transmission. These features make it an ideal choice for both residential and commercial HVAC applications.

Industrial and Commercial Uses

Mineral fiber board insulation offers reliable solutions for industrial and commercial buildings. Its durability and performance make it ideal for environments that demand high thermal efficiency, fire safety, and sound control. You’ll find this material in factories, warehouses, and office complexes, where it supports energy savings and operational safety.

Applications in Industrial Facilities

In industrial settings, mineral fiber boards help regulate temperatures in machinery rooms and production areas. Their ability to withstand high heat makes them suitable for insulating equipment like boilers, furnaces, and pipelines. This insulation reduces heat loss, improving energy efficiency and lowering operational costs.

Noise reduction is another key benefit. Manufacturing processes often generate loud sounds that can disrupt nearby areas. Mineral fiber boards absorb sound waves, creating quieter workspaces and reducing noise pollution.

Uses in Commercial Buildings

In commercial spaces, mineral fiber board insulation supports comfortable environments for employees and customers. You can use it in office walls, ceilings, and HVAC systems to maintain stable indoor temperatures. This insulation also minimizes energy consumption, helping businesses cut costs and meet sustainability goals.

Retail stores and shopping malls benefit from its acoustic properties. Mineral fiber boards reduce noise transmission between floors and rooms, creating a pleasant atmosphere for visitors.

Feature

Industrial Use

Commercial Use

Thermal Efficiency

Insulating machinery and pipes

Stabilizing indoor temperatures

Fire Resistance

Protecting equipment

Enhancing building safety

Acoustic Performance

Reducing factory noise

Improving sound quality

By choosing mineral fiber board insulation, you gain a versatile material that meets the demands of industrial and commercial applications. Its ability to balance energy efficiency, safety, and comfort makes it a valuable investment for modern buildings.

Drawbacks of Mineral Fiber Board Insulation

Limitations in Certain Environments

Mineral fiber board insulation performs well in many applications, but it has limitations in specific environments. For instance, its environmental performance can fall short in certain scenarios. A life-cycle assessment of mineral wool insulation in a Danish residential building revealed significant challenges in sustainability. This study highlighted that while the material offers excellent thermal and fire resistance, its overall environmental impact may not always align with green building goals.

Structural integrity can also become a concern when mineral fiber boards are combined with other materials. Research on incorporating waste rock wool into wood-based composites showed that while it reduced ignitability, it weakened mechanical properties like internal bonding and the modulus of rupture. This makes it less suitable for applications requiring high structural strength.

If you plan to use mineral fiber board insulation, consider the specific environmental conditions and structural demands of your project. This ensures the material performs as expected without compromising safety or sustainability.

Cost Considerations

The financial aspect of mineral fiber board insulation can influence your decision. While it offers long-term energy savings, the upfront cost may be higher compared to other insulation materials. Market studies provide insight into its economic impact.

Market Attributes

Details

Market size value in 2024

USD 17.82 billion

Revenue forecast in 2032

USD 28.52 billion

CAGR

6.0% from 2024 – 2032

These figures indicate a growing demand for mineral fiber board insulation, driven by its benefits. However, the initial investment might deter some homeowners or small businesses. If budget constraints are a concern, you may need to weigh the upfront costs against the long-term savings and benefits.

Installation Challenges

Installing mineral fiber board insulation requires precision and expertise. The boards are rigid and dense, making them harder to cut and fit compared to flexible insulation materials. Improper installation can lead to gaps or uneven coverage, reducing the material’s effectiveness.

You may also encounter challenges when working in tight spaces or irregularly shaped areas. The boards’ rigidity can make it difficult to achieve a perfect fit, especially in older buildings with non-standard dimensions. Hiring skilled professionals can help address these issues, but it adds to the overall cost of the project.

By understanding these drawbacks, you can make informed decisions about whether mineral fiber board insulation is the right choice for your needs. While it offers many advantages, addressing its limitations ensures you get the best results for your investment.

Mineral fiber board insulation offers a versatile solution for modern construction. It improves energy efficiency by reducing heat transfer, enhances safety with fire-resistant properties, and creates quieter spaces through sound absorption. Its applications span roofing systems, walls, ceilings, HVAC systems, and industrial facilities, making it a valuable choice for diverse projects.

The material’s sustainability further strengthens its appeal. Manufacturers use recycled content to produce these boards, aligning with energy conservation goals and stringent building codes. The demand for mineral fiber board insulation continues to grow due to its adaptability and performance.

Benefit

Evidence

Energy Efficiency

Mineral wool insulation boards significantly reduce heat transfer, maintaining optimal indoor temperatures and lowering energy costs.

Sustainability

Increasing awareness of energy conservation and sustainable building practices drives demand for these materials.

Compliance with Regulations

Stringent building codes, such as the EU’s Energy Performance of Buildings Directive, mandate the use of effective insulation materials.

Safety

Mineral wool insulation boards are known for their fire-resistant properties, enhancing safety in buildings.

Market Growth

The demand for both rigid and flexible mineral wool insulation boards is expected to rise due to their performance and adaptability.

By choosing mineral fiber board insulation, you invest in a solution that balances energy savings, safety, and environmental responsibility. Explore this sustainable option to enhance your building’s performance and contribute to a greener future.

FAQ

What is the difference between mineral fiber board insulation and fiberglass insulation?

Mineral fiber boards are denser and offer better fire resistance. Fiberglass insulation is lighter and more flexible but less durable. You should choose mineral fiber boards for high-performance applications like industrial buildings or areas requiring fire safety.

Can mineral fiber board insulation be used in humid environments?

Yes, it resists moisture and maintains its performance in humid conditions. However, you should ensure proper installation and sealing to prevent water infiltration, especially in areas prone to heavy rainfall or condensation.

How long does mineral fiber board insulation last?

Mineral fiber board insulation can last over 50 years with proper installation and maintenance. Its durability makes it a cost-effective choice for long-term projects, reducing the need for frequent replacements.

Is mineral fiber board insulation safe for indoor air quality?

Absolutely! Mineral fiber boards are non-toxic and do not release harmful chemicals into the air. You can use them confidently in homes, offices, and schools without compromising indoor air quality.

Can I install mineral fiber board insulation myself?

DIY installation is possible but challenging due to the boards’ rigidity. You should hire professionals for complex projects to ensure proper fitting and optimal performance. This minimizes gaps and maximizes energy efficiency.

See Also

Techniques For Producing Mineral Fiber Board Efficiently

Leave A Comment